The CB – Twin Ram Baler Series are heavy duty, versatile balers designed to process high volumes and difficult materials including cardboard, paper, rigid plastics, films, PET bottles, cans/tins/drums, PP bulk bags, MSW/SRF/RDF, steel/aluminium offcuts and more.

A key feature is their ability to swap from one material to another cleanly and quickly, due to their unique closed side door design and preset materials program. This makes them ideal for use at recycling and waste sites, transfer stations, MRFs, as well as distribution centres and manufacturing plants.

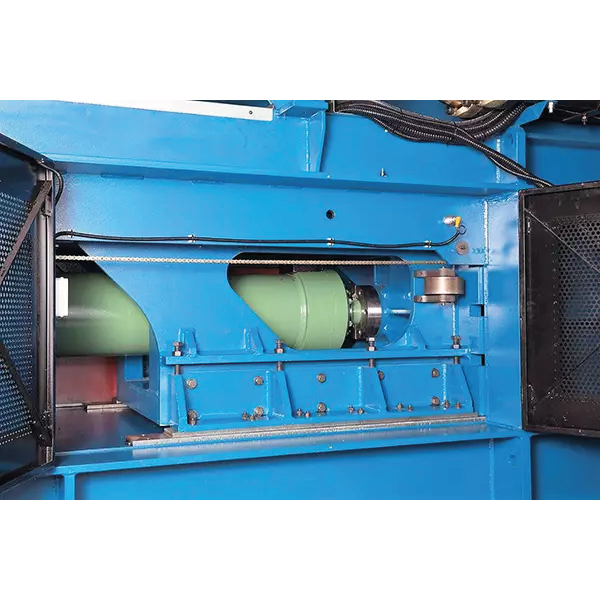

Built by a leading manufacturer in Taiwan, using Japanese steel and components, with Hardox castellated floor, replaceable triangular shear blades, Mitsubishi PLC, Parker hydraulics and Human operator interface they meet or exceed CE standards and will give decades of reliable use and low OPEX for a competitive initial investment.

In Summary

- Maximum weight bales

- Easy material changes

- Large feed aperture

- High throughput

- Heavy duty build

- Touch screen interface and preset materials program

- High-efficiency hydraulic unit

- Removable chamber wall and movable side wall

- Multi-triangle shear blade

- Full penetration and retainer dogs

- Hardox 500 liner and groove floor

- Accent tier system or CB bag system

- Fully CE compliant