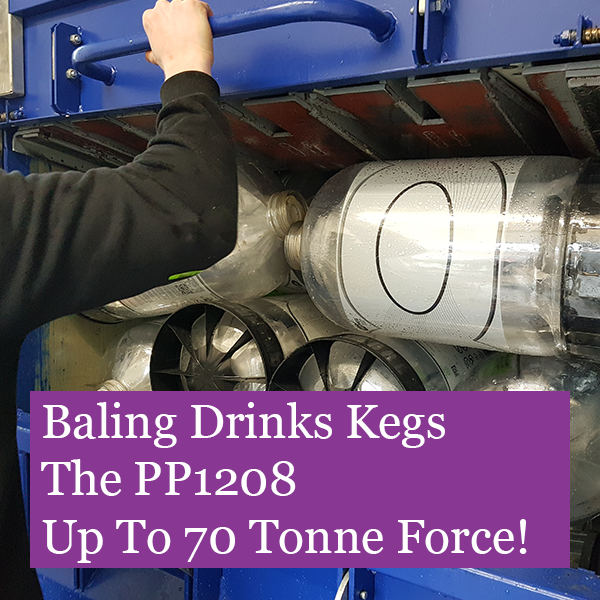

Strautmann’s German-built PP1208 is a truly industrial machine that heads the premium class of vertical baling presses worldwide. With its high pressure (58 or 70t options) and high penetration long-stroke versions, it makes dense, square-edged bales of even the most difficult to bale materials including paper, books, cardboard, film, PP bulk bags, cans, PET bottles, drums, kegs or electronic scrap.

Designed for a 50,000 operating hour lifespan in even the harshest environments, the PP1208 offers high performance, maximum reliability, optimum user comfort and safety and will repay your investment many times over through its long working life.

The PP1208 is serially equipped with patented design innovations not found anywhere else on the market.

The QuickDoor® Swing-/Sliding door for a fast, space-saving and safe filling of the press chamber.

The Press-Shield-Guiding System TopPlus® prevents any imbalance of the press plate during the compaction cycle which prolongs the life time of the baler.

The CircleSystem® reduces re-expansion of the compacted material after the press process by using down holders inside the press chamber.

The hydraulic door lock HydroClose® is a vital patented safety system that controls material re-expansion forces while opening the door with a separate cylinder to prevent unexpected door release.

The hydraulic bale ejector BaleMatic® increases user convenience. The highly compacted bale is always ejected safely and comfortably.

In Summary

- Fast, easy, safe and comfortable to load

- Large feed aperture with auto opening shutter door

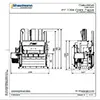

- Space saving design – Size 2075L x 1240W x 3155H (2250H for transport) mm

- Large mill size bales up to 500kg

- 24t UK lorry loads achieved

- 2 levels of hold down latches

- Massive steel construction

- Automatic band brake to ensure reliability under continuous use

- Low energy, high efficiency 4kW/5.5 kW motor

- Auto cycle and auto full

- Fast 32 second cycle time

- PLC controls with error diagnostics

- Safe bale door latch system & interlocks

- Deep slots for safe wire threading, tie off bales in minutes

- Hydraulic bale eject

- Two handed control for safe bale ejection

- Tape or wire tied options available

- In or outdoor installation