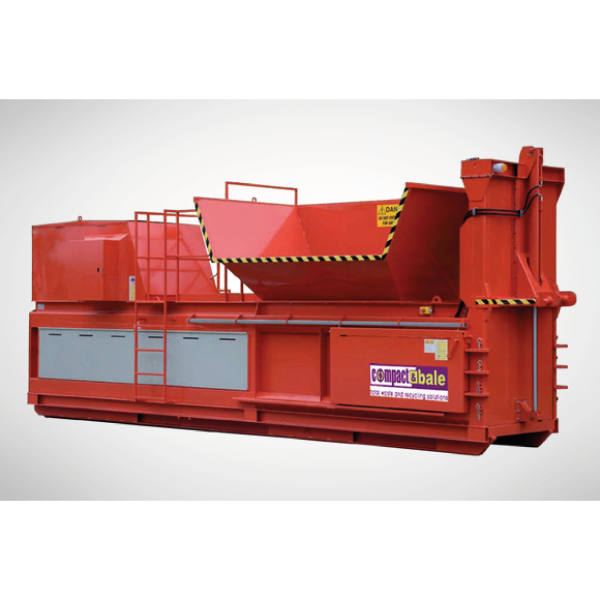

The Durapac CB58 is a fast, easy to load, versatile baler, designed for large commercial, industrial and manufacturing baling operations.

Weighing 7.25 tonne in standard fit out, it is quality engineered and designed for a 50,000 hour working life, even in the most demanding industrial baling operations.

It’s low loading height and large in feed aperture allow efficient loading of materials such as cardboard, soft and hard plastics, PET bottles, aluminium and steel cans, TetraPak®, paper trim etc.

Using a full stroke ram and 4 horizontal ties around its 750mm bale height, it is particularly effective at baling difficult materials and makes dense, square edged bales. It can be loaded from ground and dock level by hand, bin/pallet/cage tipper, forklift, chute, conveyor, air system/extraction, or bespoke applications.

In Summary

- Save labour costs with faster loading and fast running cycles

- Save space, time and money and use less baling wire with high density bales

- Make square edged bales that are easy and safe to stack and store

- Reduce power consumption and costs with our high efficiency power-pack design and motors

- Gain maximum rebates and minimum transport costs with mill quality bales

- Robust, heavy duty design, quality engineered for a long life

- Proven with over 30 years of manufacture and 100s of installations

- Vertical (Portcullis type) hydraulic end door

- Full eject of each bale makes changing materials easy

- Bales up to 500kg

- Fast cycle time of 36 seconds

- Low energy motor

- High and low pressure baling modes

- 4 wire horizontal tying

- Hardox floor and press plate base

- “V” shaped serrated, chamfered shear blades

- PLC control and error diagnostics

- Enclosed power pack and control panel – weather and vandal proof