Are you using a traditional “screw press” design polystyrene compactor?

- Needs a full time operator

- Makes briks weighing only 250-300kg/m3 max

- Suffers regular meltdowns causing expensive downtime/backlogs and needing costly repairs

- Losing out on maximum rebates due to low weight payloads

The StyroPress® is a high quality, German built machine, designed to be safe, fast and easy to use.

Its unique “cold press” design means there is no screw, no heat, no meltdowns, and so no downtime/backlogs or costly repairs.

Its fast-fill infeed shredder can be loaded at 100kg+ per hour, filling its high capacity hopper or silo and enabling auto running with no operator for up to 3 hours.

Using its optional auto delivery system, the StyroPress® will fill containers/IBC bags/octabins etc. with no operator.

The machine can either be integrated into your production process or used as a stand-alone compactor.

The automated StyroPress® will reduce the volume of your waste EPS by up to 97%, making high quality, dense briquettes that can be sold for maximum rebates in full 24 tonne payloads, whilst minimising both transport and labour costs.

How does it work?

The extra-large feed opening of the StyroPress® shredder enables loading of both large sizes and volumes of material. EPS packaging from white goods/large appliances, TVs, furniture, etc. are easy, safe and fast to load at 100kg+ per hour. The shredded material is transferred to the loading hopper or optional 7.5m3 silo from where it is dose-fed into the compaction chamber.

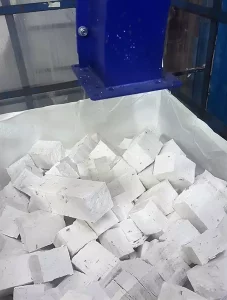

The hydraulic “cold-press” applies 25 tonnes of pressure on a 120mm2 press plate which achieves unparalleled compaction, giving a 97% volume reduction. The dense, square-edged briquettes are delivered at a rate of 30kg+ per hour, and are quick and easy to handle and stack on pallets.

When using the auto delivery system the briquettes break themselves into blocks that drop into your choice of container, IBC bag or octabin, etc..

In Summary

-

- Proven German manufacturer

- Hundreds of machines supplied worldwide

- Heavy duty design, proven long life

- No heat/friction so no melt-downs/jam-ups

- Volume reduction by up to 97%

- Dense briquettes weighing up to 700kg/m3

- 24 tonne payloads – maximum rebates

- Low power consumption

- Large infeed aperture for easy loading

- Integral shredder

- Optional 7.5m3 silo

- Loading speed – 100kg+/hour

- Delivery speed – 30kg+/hour

- 1 hour loading = 3 hours auto running

- Error code messages for diagnostics

- Safe system & interlocks

- Space saving design – 3510L x 1650W x 2140H mm

- Quick ROI due to maximum cost savings/rebate values and minimum labour requirements