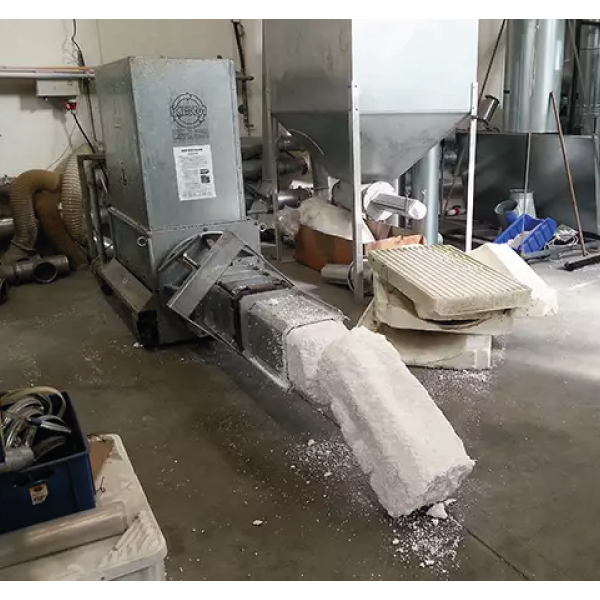

The KBM Maxi is a high performance, high throughput briquetting press with a choice of three models that compact between 70-130kg per hour of Expanded Polystyrene (EPS) into blocks weighing 250-350kg/m3. This equates to up to 200 fish boxes per hour.

With its compact footprint, it is ideal for sites where volumes are high but space is limited. This machine is suited for large recycling companies, industrial producers and municipal waste collection sites.

It is fully galvanised and fitted with robust, locking wheels so it can be moved around easily when required.

The machine is simple to use and can handle both wet and dry EPS, as well as EPE and EPP foam. The large feed opening (up to 560 x 1400mm) handles most sizes of material with ease and the vertical feed means any length may be loaded.

An optional interlocked lid allows users to fill the hopper, close the lid and leave the machine to run safely, and automatically shut down after a pre-set time period.

All KBM machines feature a unique integrated pre-crush system.

Inside the feed chamber, the auger screw is fitted with cutting knives that shred the EPS as it is compacted. This system increases throughput and reduces jamming, melting and breakdowns.

The auger screw is also fitted with a patented double flight system that ensures it spins straight, even when under full load. This reduces wear, avoids the need for additional bearings and supports on the auger and significantly increases the lifespan of the motor and gearbox.

In Summary

- Proven Danish manufacturer since 1978 – largest in Europe

- Heavy duty design, proven long life

- Energy efficient 7.5/11kW motors

- Compacts up to 130kg per hour

- Large infeed aperture for vertical feed

- Mobile

- Optional interlocked lid with auto shut down

- Patented auger screw design reduces wear and breakdowns

- Fully galvanised

- Also compacts EPE and EPP