Waste Compactors

Keep your costs down and your payloads high

Our range of waste compactors use 24 – 38+ tonnes of pressure, achieving up to 10:1 compaction ratio, to consistently compact high payloads on a wide range of waste materials.

All our machines are quality built to CHEM standards and are typically loaded by hand or automatic bin lifter from ground or dock level.

-

MT240 240 Litre In Bin Compactor

Wheelie Bin CompactorUsing an in bin compactor can reduce residual waste by up to 85%.

Suitable for 240L wheelie bins, the MT240 will give you more space in your bins, saving both disposal costs and space on your site!

Materials: General Waste, Cardboard, Paper & Recyclables.

- Compactor Type

- Bin

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

RC1100 660-1100 Litre In Bin Compactor

Wheelie Bin CompactorSuitable for 660-1100L wheelie bins, the RC1100 660-1100 Bin Press series will save you space and costs, while protecting your bins ensuring a long working life.

Typical volume reduction up to 85%.

Materials: General Waste, Cardboard, Paper & Recyclables.

- Compactor Type

- Bin

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

Model AS Skip Portable Compactor

Portable CompactorsThe Model AS is collected for emptying by a skip lorry and typically holds 4-5 tonne of waste.

It uses a straight push compaction ram with twin cross-over cylinders enabling fast, effective compaction of large sizes and volumes of material.

With its small footprint it is easy to position where space is tight and loading is typically by hand or bin lifter.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper & Recyclables.

- Compactor Type

- Portable

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

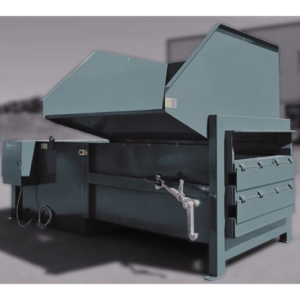

CB1250 Static Compactor

Static CompactorsAre you paying for skips full of fresh air?

Is your waste bill getting away from you?

Does your site look a mess?

Durapac’s CB1250 compactor saves users £1000’s each year while solving these problems and more!

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper & Recyclables.

- Compactor Type

- Static

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

Model APK Skip Portable Compactor

Portable CompactorsThe Model APK is collected for emptying by a skip lorry and typically holds 4-5 tonne of waste.

It uses a pendulum compaction ram with self-cleaning cylinders housed in the top of the machine, all waste build up and required cleaning is completely avoided.

This means there is no inspection hatch, filth, stench, routine operator cleaning (that never gets done!), and so no expensive breakdowns, replaced hoses, cylinders, pins, bushes, etc. (all common problems with standard “straight push” design machines) and thankfully no more hassle!

Materials: General Waste, Wet Waste, Food Waste & Offensive Waste.

- Compactor Type

- Portable

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste, Wet / Food

- Weekly Volume

-

CB1250SS Short Static Compactor

Static CompactorsIs your site tight on floor space?

Is waste literally taking over?

Have you been told you can’t fit a compactor in?

The Durapac CB1250SS is the smallest compactor we’ve ever seen!

At just over 2m length, it offers a remarkable 1.77m3 charge box volume, and will make light work of your waste problems.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper & Recyclables.

- Compactor Type

- Static

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

Model N Roro Portable Compactor

Portable CompactorsThe Model N is collected for emptying by a roll-on-off lorry and typically holds 8-12 tonne of waste.

It has a massive infeed chamber suitable for large items and volumes of waste and uses powerful twin-cylinders and a straight push ram.

It is typically loaded from ground or dock level by hand or bin lifter and needs no special flooring.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper & Recyclables.

- Compactor Type

- Portable

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

Model L Roro Portable Compactor

Portable CompactorsThe Model L is collected for emptying by a roll-on-off lorry and typically holds 8-12 tonne of waste.

It has a massive infeed chamber suitable for large items and volumes of waste and uses powerful twin-cylinders and a straight push ram.

It is typically loaded from ground or dock level by hand or bin lifter and needs no special flooring.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper & Recyclables.

- Compactor Type

- Portable

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

Model RPK Roro Portable Compactor

Portable CompactorsThe Model RPK is collected for emptying by a roll-on-off lorry and typically holds 8-12 tonne of waste.

It uses a pendulum compaction ram with self-cleaning cylinders housed in the top of the machine, all waste build up and required cleaning is completely avoided.

This means there is no inspection hatch, filth, stench, routine operator cleaning (that never gets done!), and so no expensive breakdowns, replaced hoses, cylinders, pins, bushes, etc. (all common problems with standard “straight push” design machines) and thankfully no more hassle!

Materials: General Waste, Wet Waste, Food Waste & Offensive Waste.

- Compactor Type

- Portable

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste, Wet / Food

- Weekly Volume

-

CB1500 Static Compactor

Static CompactorsThe Durapac CB1500 is one of our top selling compactors for industrial and commercial operations.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper, Recyclables & Wood / Pallets.

- Compactor Type

- Static

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume

-

CB2100 Static Compactor

Static CompactorsThe Durapac CB2100 static compactor is ideal for dry waste or recyclables.

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper, Recyclables & Wood / Pallets.

- Compactor Type

- Static

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

-

SVS "Electric Drive" Static Screw Compactor

Static CompactorsSaves up to 80% on waste transport costs

Uses up to 50% less energy costs

Continuous and quiet running

Reliable in all environments

Suitable for all applications

Significantly reduced maintenance costs

Extremely GREEN CO2 saving

The Eco-Future of waste disposal

Materials: General Waste, Dry Mixed Recycling, Cardboard, Paper, Recyclables, Wood/Pallets & Dry Food Waste/Dough.

- Compactor Type

- Screw, Static

- Waste Material

- Cardboard / Paper, DMR / Recyclables, General Waste

- Weekly Volume