Ludden & Mennekes’ RPK range of sealed portable compactors are high quality German built machines, designed for sites with medium to large volumes of waste.

When full, they are collected by a hooklift lorry for transport to disposal, typically holding 8-12 tonnes, depending on materials.

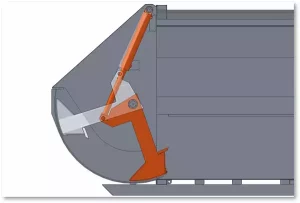

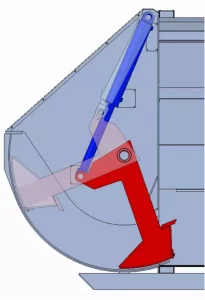

Using a self-cleaning pendulum ram, the RPK is specifically designed to compact wet, food, organic and offensive waste.

With container sizes ranging from 14-24m3, the RPK portable compactor offers high performance, small footprint and low maintenance.

It can be sited on tarmac, block-paving, rough ground, etc. as it does not require permanent fixings.

Its design completely avoids any possibility of waste and liquids building up behind the ram, which entirely removes the need for unpleasant cleaning and reduces the risk of expensive breakdowns and repairs.

As standard, all RPK compactors have:

- A press force of 37 tonnes

- A fast 35 second cycle time

- Filling level warnings (75% and/or 100%)

- A very quiet running hydraulic pump

- High quality steel compaction chamber floor

- Surface lacquered finish (including corrosion Protection Class C 3)

- Continuously welded seams = prevents corrosion

- Integrated hydraulic unit located in the top front part of the container

- Pressure monitoring manometer with shut-off valve

- CEE plug with integrated phase change & main switch

- Time relay for controlling the runtime of the compactor

- Declaration of conformity & documentation

- CE and GS approved

They are offered with a choice of side or top hung rear door, rubber seals to prevent leaks and optional liquid drain-off valves.