We are proud to supply these wheelie bins made in Haan, Germany.

They undergo strict testing so you can be assured these bins are high quality and made to last.

Suitable for any climate, these bins are heat and frost-proof, and will not rot or be damaged by chemicals.

They are the ideal solution for waste disposal on a small scale.

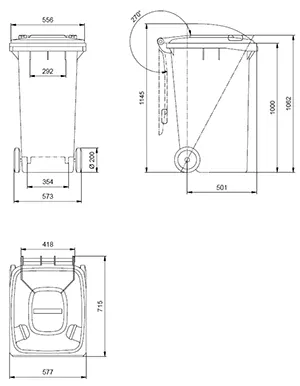

With two wheels and a handle at the back, they are easy to move around.

Please note, any bins requiring modifications or additions are not available for next day delivery.

If you have any further questions about our products, please contact our consumables team and they will be more than happy to assist.