The BaleTainer® is a high quality, fully automatic, continuous feed baler, designed to be safe, fast and easy to use. Loading large sizes and volumes of materials (even cardboard pallets) is safe, quick and easy through the large rear feed opening.

Due to it’s massive rear infeed, the BaleTainer® is uniquely suited to stand-alone, off-dock, through-wall and chute fed applications and can be loaded by hand, machine, bin tipper, extraction and conveyor.

With 60t compaction force and a heavy duty integral spiked-rotor, the BaleTainer® produces dense bales of cardboard, paper, polythene film, PET bottles, steel/aluminium cans, TetraPak® cartons, foil juice packs and more.

It produces euro-pallet size bales typically weighing 400kg. With its small footprint and fully weatherproof design, it is suitable for both internal and external installation. It is also fitted with sliding door guards and Seculock safety keys for complete operator safety.

The BaleTainer® features a number of labour-efficient, patented systems that guarantee a long working life and low operating costs.

How does it work?

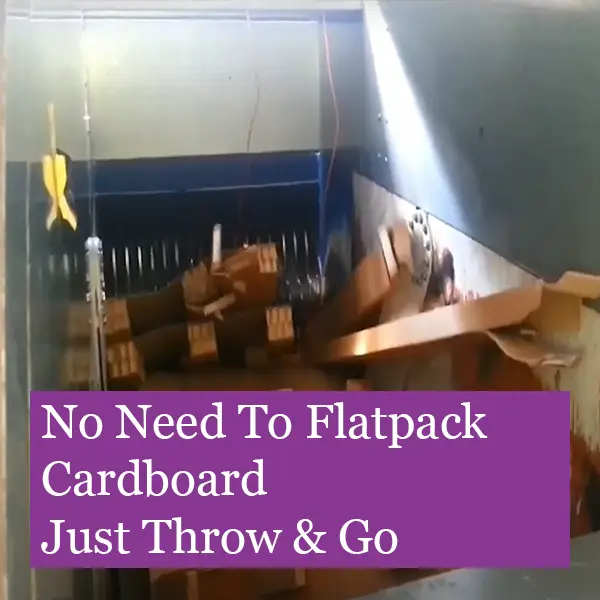

The massive feed opening of the BaleTainer® (2870L x 1069W x 2000D mm approx.) enables insertion of both large size materials such as furniture boxes, octabins, cardboard pallets and high volumes of materials such as 40+ standard clothes boxes or a full pallet of standard tri-wall fruit trays. A hydraulically operated swing plate scoops the material automatically from the bottom of the chamber and forces it into the rotor. Emptying the material from the bottom of the chamber enables continuous filling from the top.

The rotor shreds the material and fills the press chamber and the 120 tonne equivalent press plate automatically compresses a bale slice, three of which are tied together to make a full Mill Size bale weighing approximately 400kg. The bales are automatically tied and continuously ejected from the machine.

In Summary

- Proven German manufacturer

- 100s of machines supplied worldwide

- Heavy duty design, proven long life

- Efficient wire usage (2.8mm diameter)

- 1000 hour service intervals

- Special, reinforced version for PET

- Handles octabins, cardboard pallets, tri-wall boxes, etc

- Fully automatic operation

- Truly continuous feed

- Cardboard bales typically 400kg

- 24t UK lorry loads achieved

- Massive infeed aperture

- Fully guarded sides and roof

- Error code messages for diagnostics

- Seculock key interlocks

- Internal or external installation

- Space saving design

- Quick ROI due to labour savings